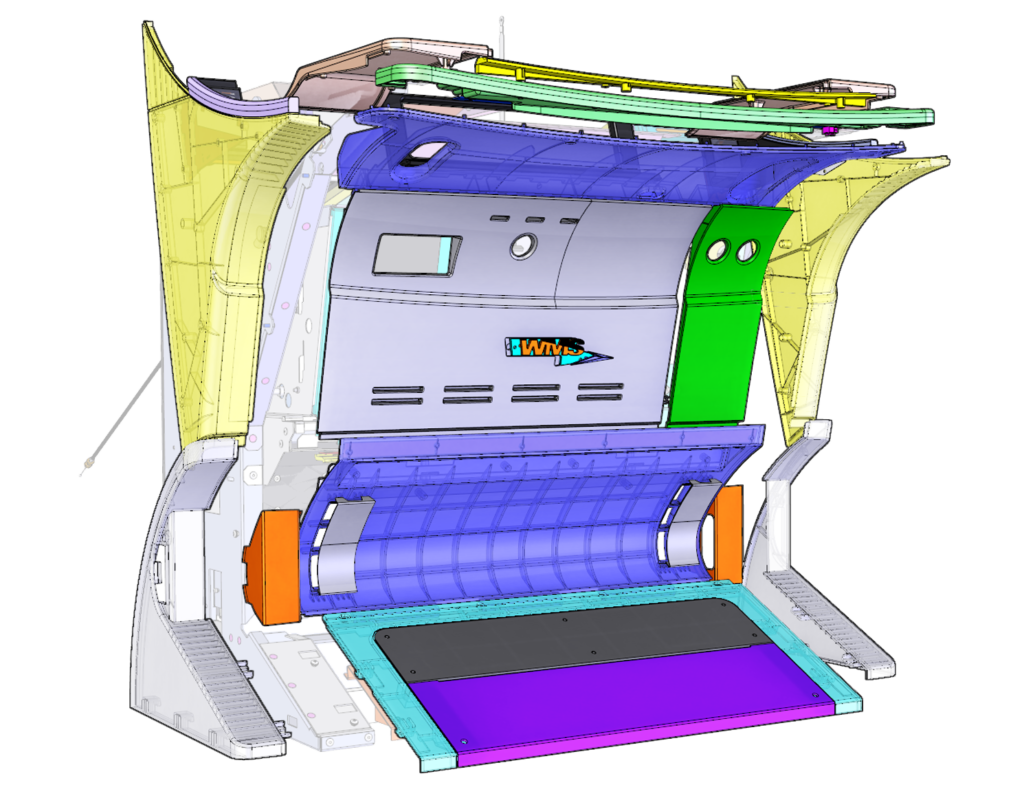

DiMonte Group collaborated with WMS Gaming to create their cutting-edge Blade video slot machines. We leaned on our existing slot machine design experience to develop the shared lower core and two different configurations of the upper cabinet, bringing to life the concepts envisioned by WMS’s industrial designers. With our deep expertise in sheet metal and plastic part development, we successfully met WMS’s tight project timeline.

The work was broken up into three separate projects, each showcasing our expertise in product design and problem-solving.

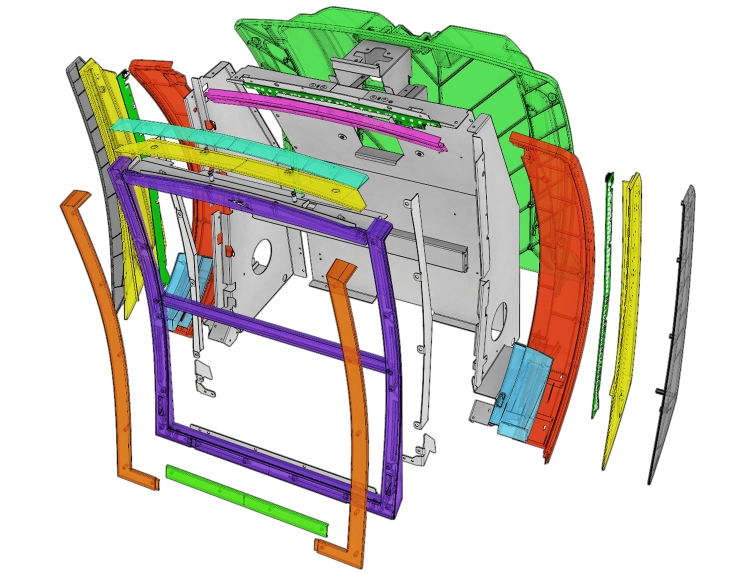

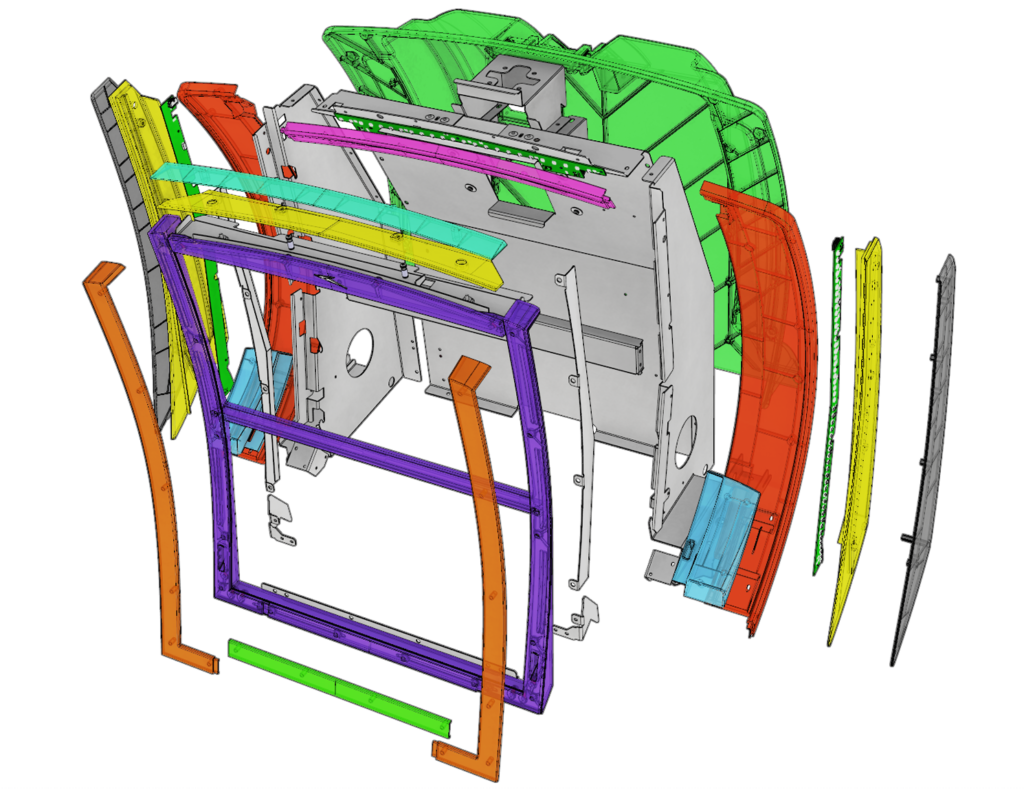

Beginning with conceptual industrial design models, we transformed these ideas into practical, manufacturable components. This involved detailed design work for plastic, sheet metal, and die-cast elements, plus light pipe design and planning out the assembly order.

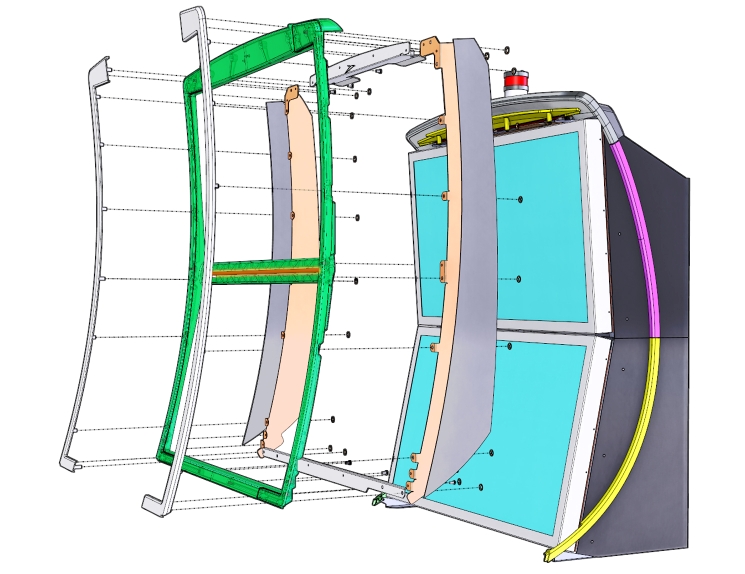

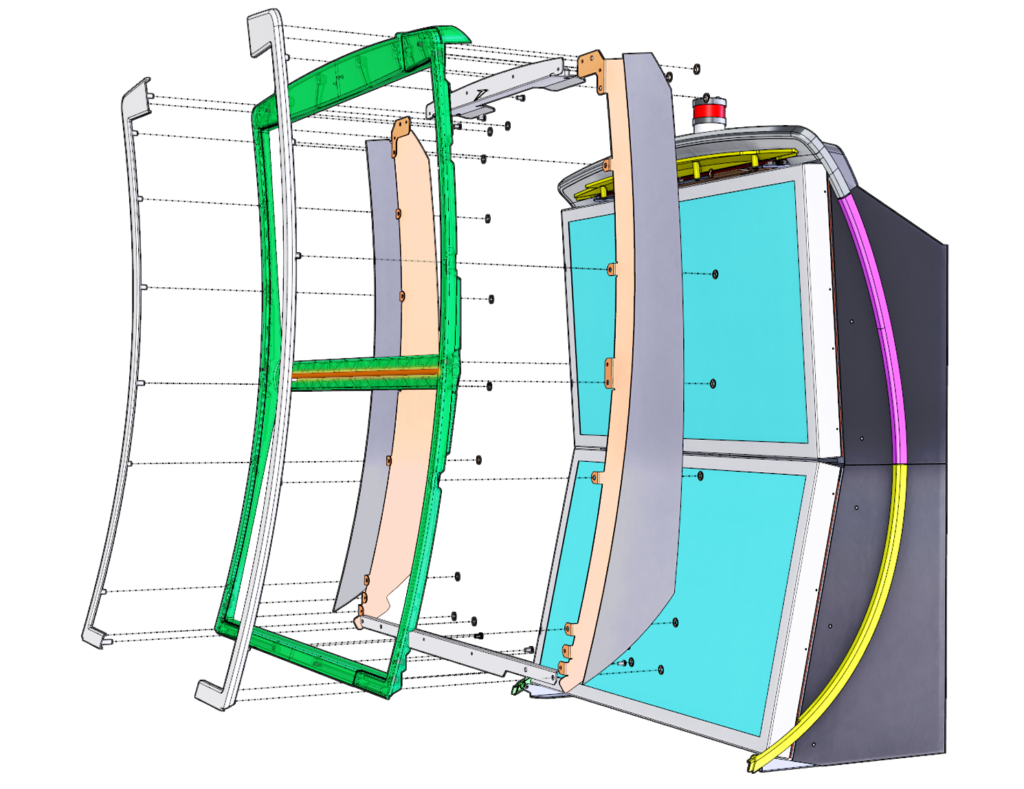

Building on the success of the smaller S23 cabinet, WMS entrusted us with the task of redesigning and cost-reducing the larger S32’s upper cabinet. We devised a one-piece reaction injection molded (RIM) bezel covering both 32” monitors. We also engineered sheet metal support structures to facilitate the easy removal of the heavy monitors for servicing. Through numerous iterations, we developed a liquid-resistant assembly for the Blade S32’s distinctive 10.4” upward-facing touch screen.

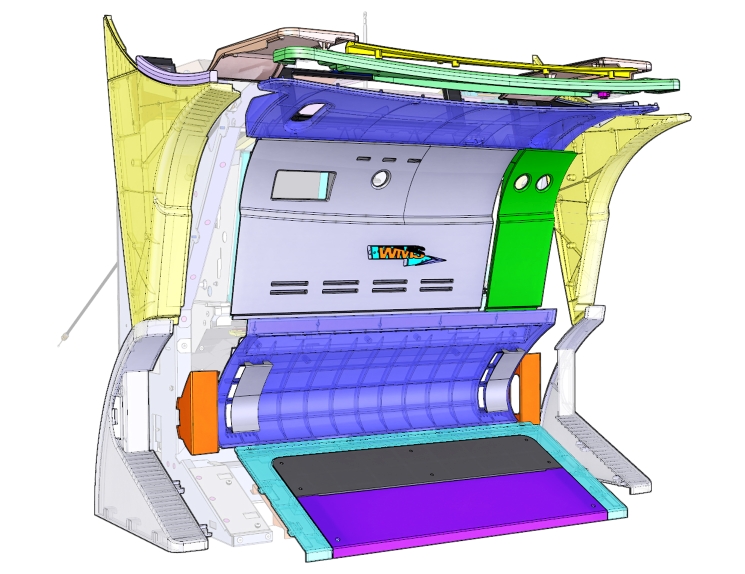

The Lower Core project aimed to streamline assembly and reduce tooling costs by creating a common base for both the S23 and S32 models.

This assembly supports the upper deck and also acts as a convenient footrest. The front lower panels are designed to hinge open, providing access to the cash box and electronic service components inside.

Explore this project through the links below: