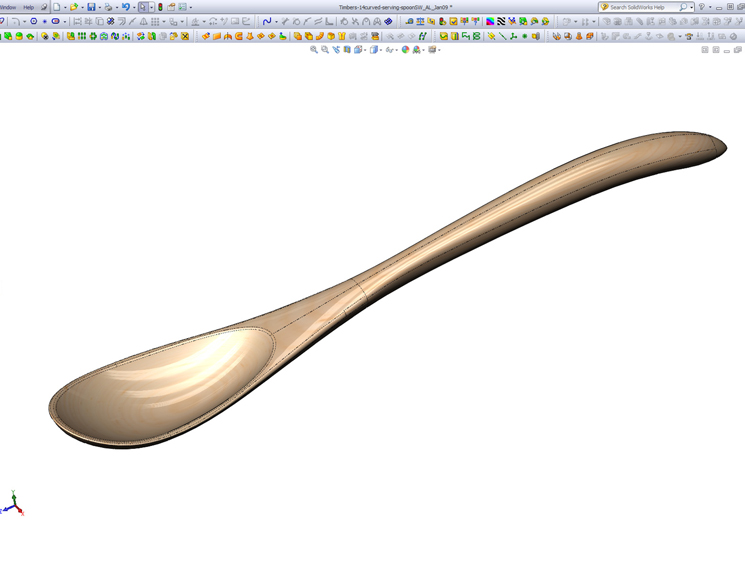

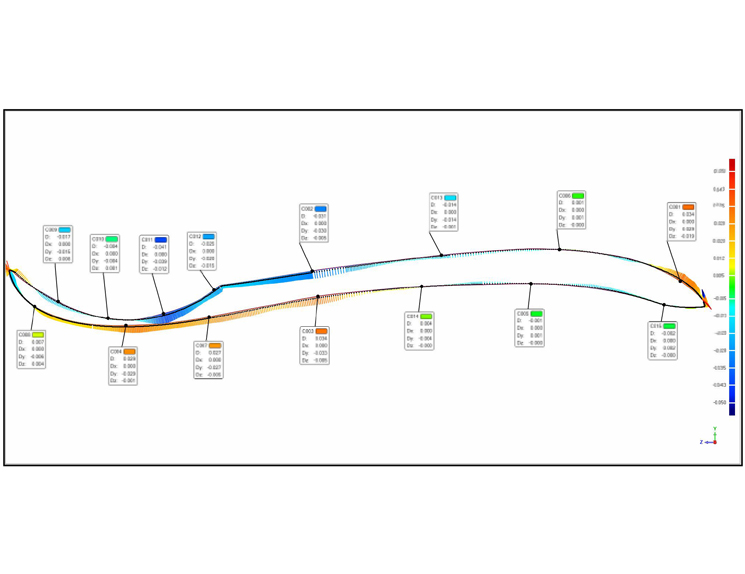

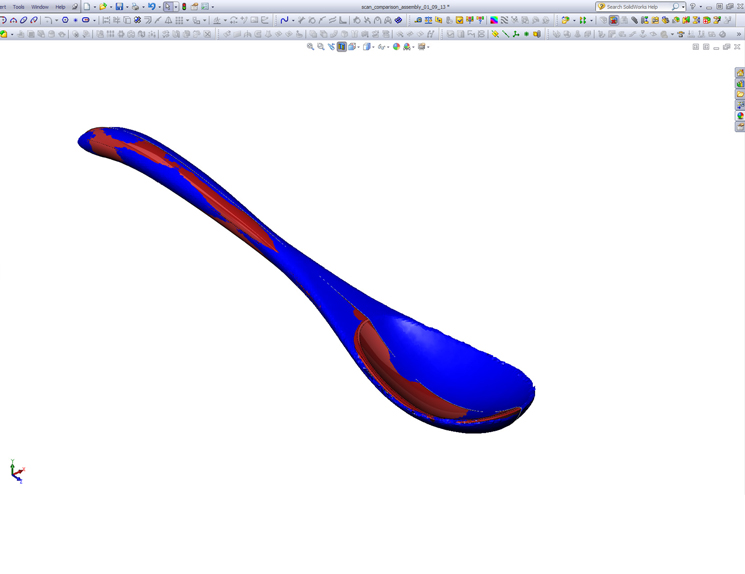

DiMonte Group worked with Timbers Wooden Spoons to produce accurate SolidWorks models of their hand crafted wooden spoons. Wooden spoons were first 3D scanned, the scan data cleaned up in Geomagic Qualify, and finally STL files were imported into SolidWorks. Modeling progressed from there. After SolidWorks modeling was complete, the newly modeled spoon was compared to the original scan data.

Finally, the SolidWorks model was 3D printed and compared to the original spoon to ensure that the feel of the hand crafted was captured accurately in the CAD data.