Problem

Fellowes approached DiMonte Group with the idea of integrating a suction mechanism into a tablet stand. Fellowes had styling concept sketches and contracted DGI to transform the idea into a functional product though prototypes and CAD, optimized for manufacturing and assembly.

Research

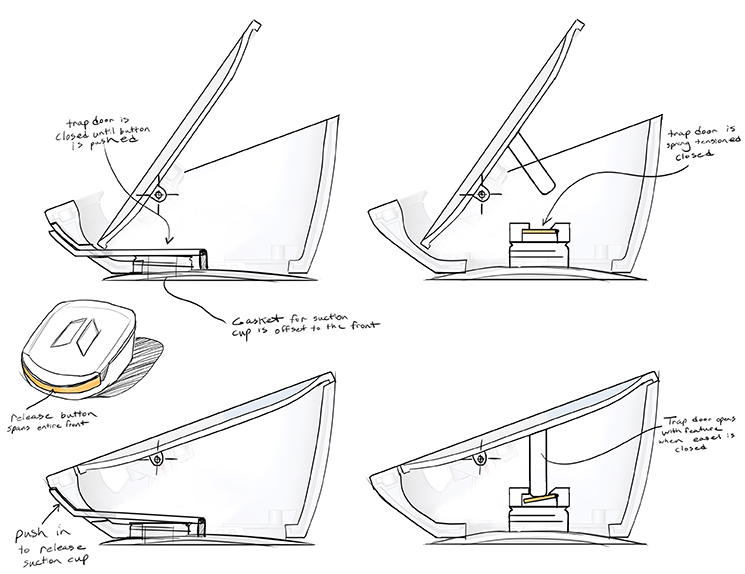

DiMonte Group created a dimensional matrix of existing tablets for sizing and conducted research on existing suction mechanisms in the market to gather ideas and start the ideation process. DGI then transitioned into reverse engineering and exploring how the suction cup mechanism would work.

Design and Prototype

DiMonte Group produced several prototypes, with varying levels of complexity, to efficiently solve problems:

- Foam core mockups to quickly work out the optimal angle and center of gravity for tablets, and to ensure multiple tablet compatibility

- Proof of concept, high-level mechanical prototype to validate suction strength and to explore initial suction actuation concept

- FDM 3D printed models to confirm suction and actuation concepts

- SLA models to validate the production design

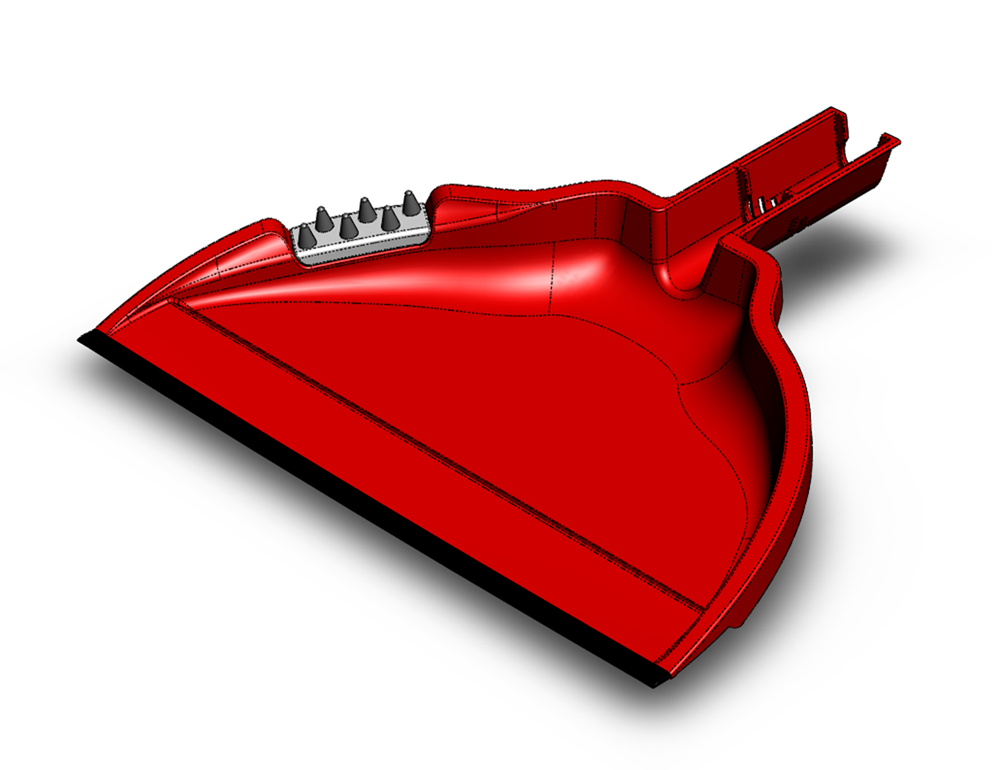

Deliverables

DiMonte Group delivered a production ready CAD design along with 2D production drawings. Through DiMonte Group’s creative and efficient solutions, Fellowes was able to drive the product successfully into the market.