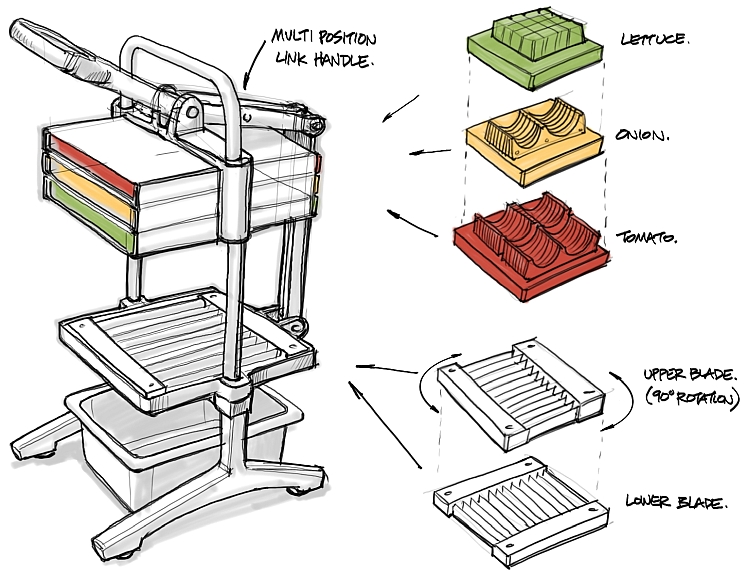

Quick service restaurants like McDonald’s and Burger King slice lots of tomatoes, onions, and lettuce, using dedicated slicing machines for each produce item and cut size. Prince Castle engaged DiMonte Group to combine the functionality of three products into one universal system, increase capacity and save valuable time and counter space.

R&D

We started by measuring and slicing hundreds of tomatoes, onions, and full heads of lettuce using single-product slicing tools available on the market. We tested variations in produce size, ripeness, variety, and orientation to see how slicing was affected. We quickly learned a lot about blade design and tensioning, and determined the best method to slice each food item. We also identified opportunities for new safety features and improved cleanability over existing products.

Design & Prototyping

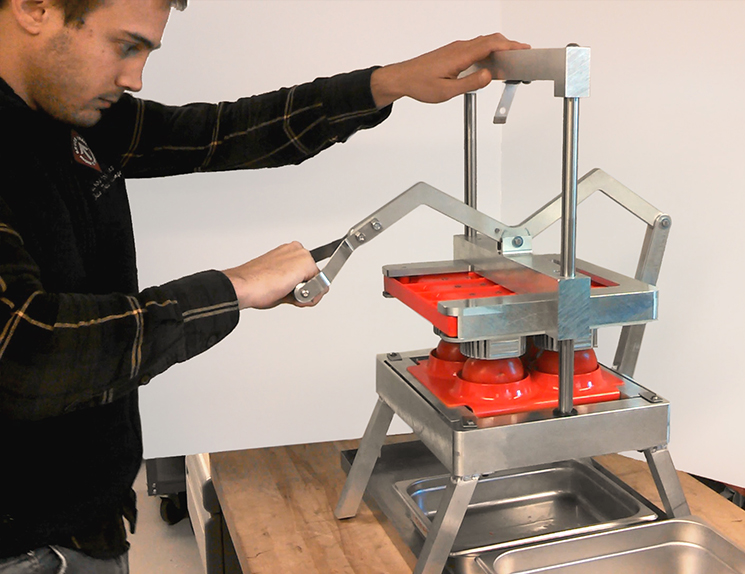

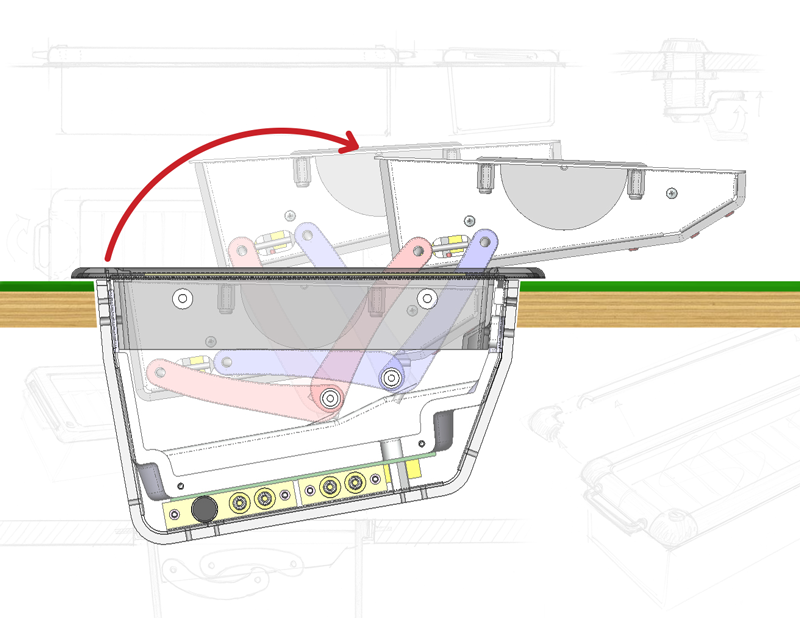

Through several cycles of design and prototyping, we developed a robust and flexible system that fits within the space constraints of the targeted restaurant environment.

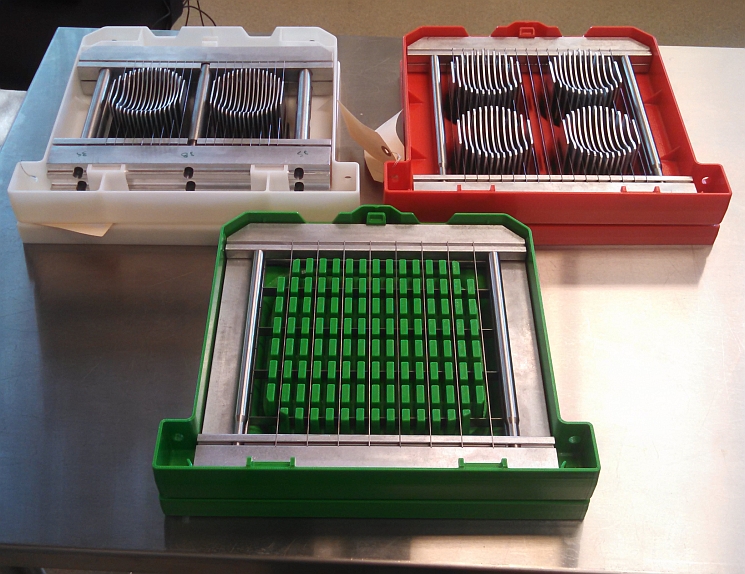

- Patented blade covers control produce placement and reduce injury risk during use and cleaning

- Safety latch keeps both hands clear of blades and pinch points

- Unique pusher heads were designed to eliminate tolerance stackup issues found in competing products, ensuring precise alignment and enabling slices as thin as 3/16”

- FEA simulations ensured plastic snap features would survive 5+ years of rigorous use and abuse

With this universal platform established, Prince Castle engineers can now develop additional interchangeable blade & pusher sets to slice nearly anything their customers need. The final product is available for sale HERE and is currently being used in restaurants.