Cornelius approached us with an opportunity to increase efficiency in Burger King drive-thrus. Implementing a drink pouring robot that perfectly pours fountain drinks would free up a significant amount of time for the window staff to tend to other things like fries or bagging food. At the project kickoff, all we had to go off of was the problem statement, a three-month deadline and two fountain drink machines to tear apart. Our multidisciplinary team was able to create a beautiful, functional, and manufacturable prototype that Cornelius debuted at the 2015 Burger King Convention.

This video shows our prototype in action.

How It Works

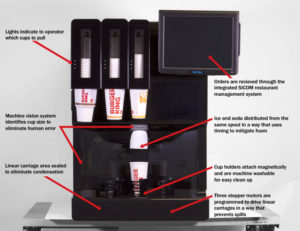

When a drive-thru order comes in through the integrated restaurant management system (SICOM), lights on the Quick Serve Pro’s cup dispensers indicate to the window worker which cup sizes need to be placed into the holders. The cups can be placed in any order and the machine vision system will identify the sizes of the cups. The machine then automatically moves each cup holder under the nozzle, filling them with the correct soda order. The whole process takes under 30 seconds and the only human input is placing empty cups in holders and retrieving the cups once they are full.

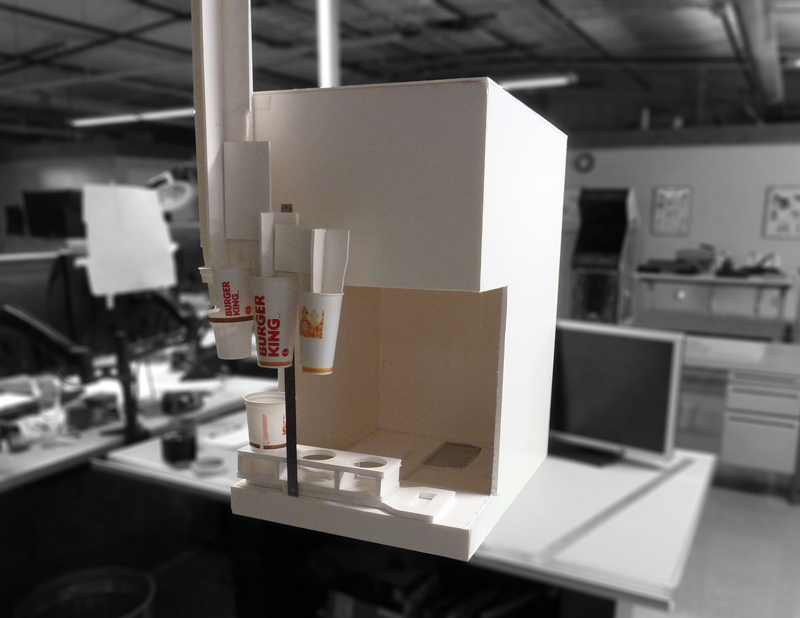

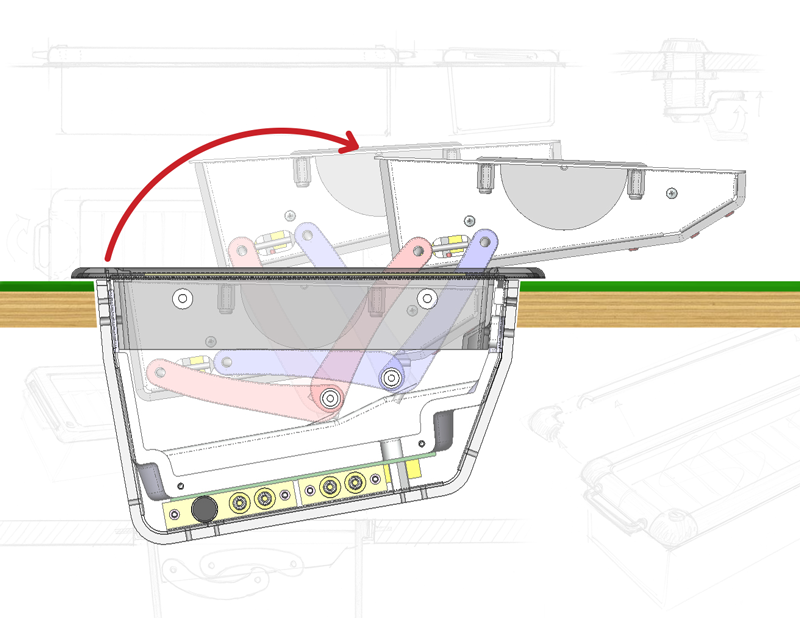

Rapid Prototyping

We were able to design and build a developed prototype within the deadline, that exceeded client expectations because of the concurrent and collaborative efforts of the mechanical engineers, industrial designers, software developers and electrical engineers on our team. One particular challenge we faced was designing a way for the machine to move the cups from a base position to a position under the nozzle. We experimented with multiple designs before landing on the solution of using magnets to connect the cup holders with a linear carriage located under the drip tray. The magnets connect through the plastic drip tray, which acts as a barrier to protect the mechanical parts of the linear carriage (electrical components and stepper motors) against liquids. This solution also means that the cup holders are easily removable and machine washable. The final prototype satisfied ergonomic, spatial, and SICOM system requirements while also looking like it fit into the Cornelius product catalog.