Controlling the motion of heavy lids or panels is a common requirement for safety and usability of a product. Precise load balancing through the full range of motion involves many variables and iterative calculations.

DiMonte Group has developed an innovative process that uses excel algorithms paired with SOLIDWORKS to simplify the implementation of gas spring assist in various applications, eliminating guesswork and reducing the need for costly and time-consuming prototype iterations.

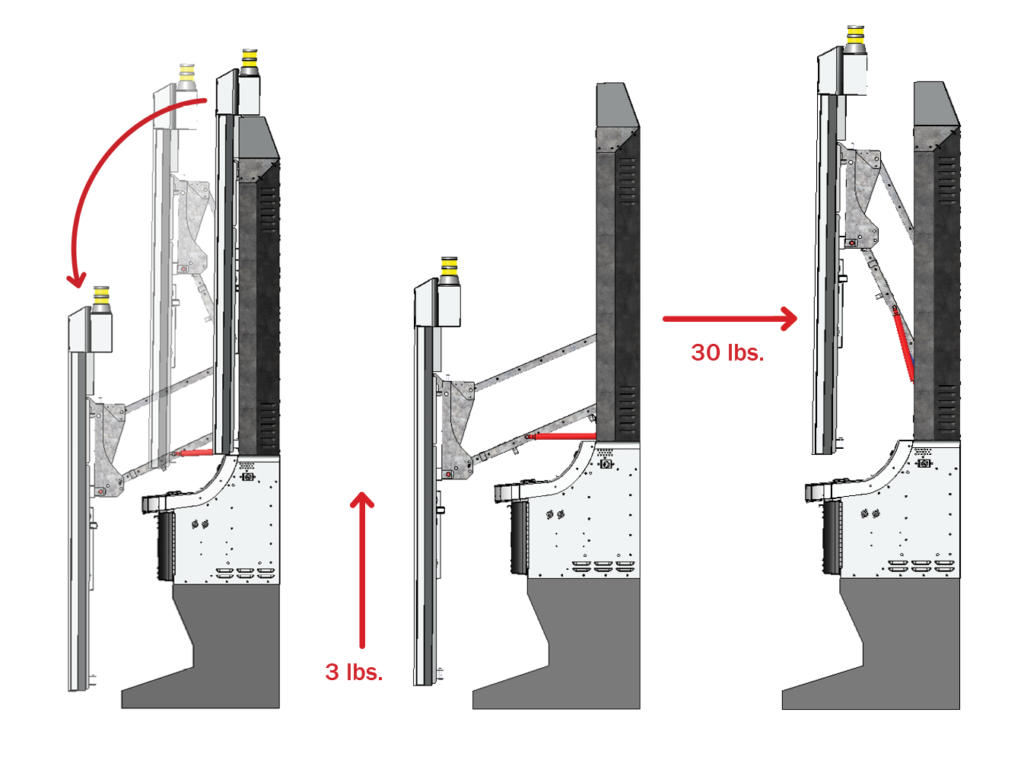

Project #1 – Incredible Technologies – V55 Slot Machine

These cabinets feature hefty 55” flat screen displays that need to be serviced from the front. Our solution involved mounting the displays on parallel joists supported by two gas springs and two dampers.

This creative setup transformed the experience, eliminated slamming, and made a 100 lb. screen feel like 3 lbs. when lifting and a mere 30 lbs. when pushing to close. Two dampers make the screen lower slowly under its own weight, rather than slamming open.

The mechanism we designed using our algorithm worked on the first prototype and was rapidly implemented into production.

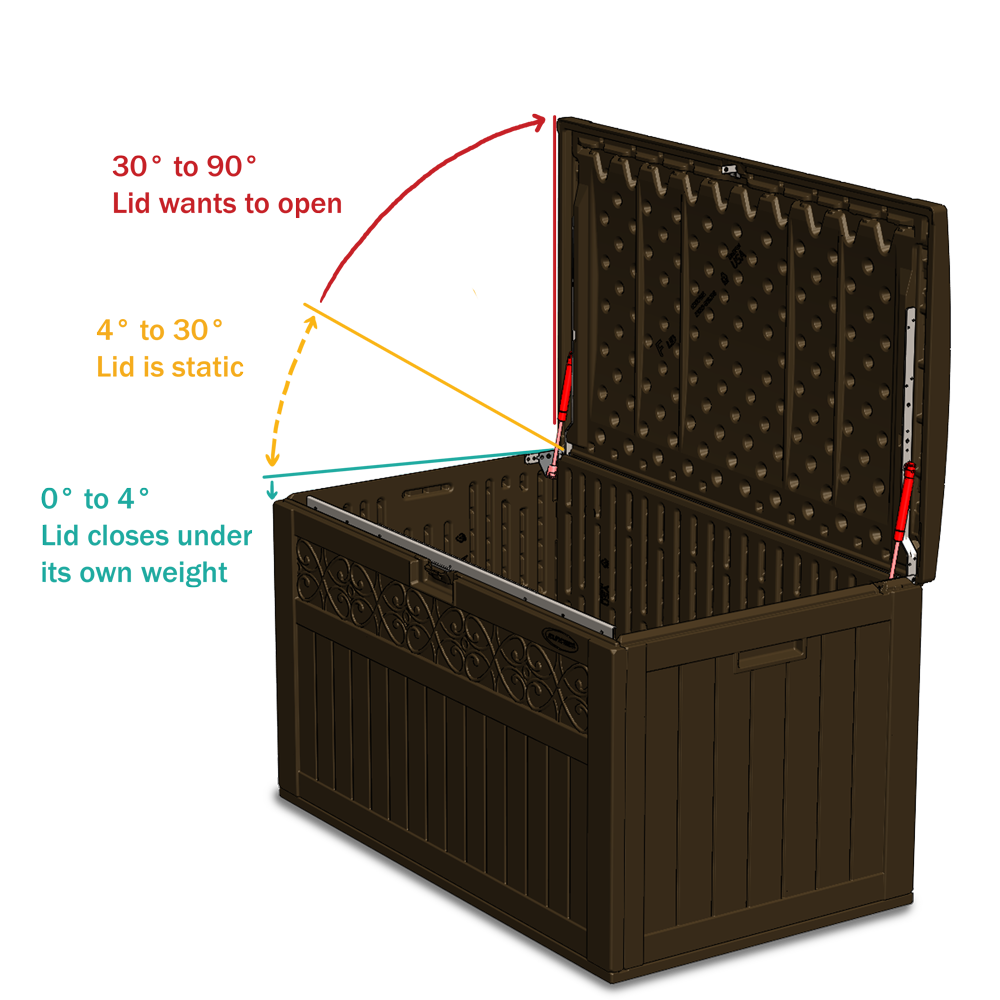

Project #2 – Deck Box

Our client tasked us with designing a soft-close lid for a large 135-gallon deck box. The weight and feel of the 11.5 lb. lid is a huge selling point for a product like this, so it needed to be perfect. Using our proprietary algorithm, we were able to quickly deliver a soft-close system that our client implemented into production meeting all of their constraints, including:

- When closed to a 4° position, the lid should gently fall into place

- From 4° to 60° from closed, the lid must not drop more than 0.5” under its own weight, preferring to open

- Pinch point gaps must be less than .19” or greater than .5” through the whole travel arc

- Less than 10 lbs. force required to open lid at any point

- Must still work after 3,500 cycles